Printing to a surface

Bespoke printed solutions tailored to you

Our printing capabilities mean that we can print direct onto almost anything as long as it’s flat. From our state-of-the-art in-house production facility, we offer digital printing, surface printing and direct flatbed printing to a variety of materials for both indoor and outdoor use, including Foamex, Dibond and MDF, to acrylic, toughened glass, wood, leather and even ceramics. Why not challenge us with something new?

PRINTING TO FOAMEX

PVC foam sheet (Foamex) is a lightweight material with good mechanical and insulation properties. It has good chemical resistance, with low water absorption and is suitable for indoor and outdoor use. It has low impact strength and due to its range of colours it is often used for signage and displays. It is available as a solid acrylic sheet, in four thicknesses: 3mm foam PVC, 5mm Foam PVC, 10mm Foam PVC and 19mm Foam PVC. It is also available in both white and black finishes.

It’s main use is for signage, sign letters, banners and exhibition display panels and is the preferred choice due to its fine cell structure and high-quality smooth finish. Foamex is easy to cut to shape, allowing designers to create attractive graphic panels for exhibitions and advertising applications. It is a cost-effective alternative to plywood, Dibond, MDF and aluminium, and is extremely durable with a life expectancy of 5-7 years.

Foamex is a strong, rigid material, and can be fixed to many different surfaces in a whole host of different ways and using different methods. Foamex is classified as a recyclable material.

PRINTING TO MDF

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres and combining it with wax and a resin binder, to form panels by applying high temperature and pressure.

MDF is generally more dense than plywood and benefits from cost savings compared to real wood. It’s very strong and has high moisture resistance, preventing unwanted warping.

We can print customised designs onto MDF and easily cut and machine it into bespoke shapes and sizes, making it a sustainable and eco-friendly solution for signage and wayfinding for outdoor events and festivals. The strong, smooth characteristics of MDF make it an ideal core material for components that require intricate shaping, or surfacing operations.

PRINTING TO LEATHER

MX Display can offer short custom runs, as well as long production runs, with no size limitations (except the size of the skin). We can print images on leather panels, as well as pre-cut patterned pieces.

The ability to apply graphics to leather provides designers with unlimited opportunities to create unique and bespoke leather pieces, allowing for truly one-off customised solutions.

PRINTING TO CORREX

Corrugated plastic or corriboard refers to a wide range of extruded twin wall plastic-sheet products produced from high-impact polypropylene resin. Predominantly used in the printing industry for signage, the benefits of Correx are that its cost-effective, lightweight, waterproof and also recyclable.

We recommend using Correx for short-tern signage solutions, or when a high-quality premium product is not necessary or imperative, such as for directional signage used for a music festival or temporary signage for construction and building sites.

PRINTING TO GLASS

Glass printing covers a vast array of applications, from decorative to architectural. For many years glass has been screen printed however, more recently, glass printing has embraced the benefits of digital inkjet technology to address the need for single pieces and short runs. Digital printing can be particularly beneficial for glass applications such as imaging on building windows, doors, interior design features, splashbacks and shower screens.

In the commercial and domestic interior design environment, glass can solve a range of creative and functional challenges. For example, printed glass can be used to diffuse unwanted light, offer UV protection and add security while on the decorative side.

Glass adds colour and light, and brightens up interiors, allowing you to be creative with partitions, room dividers or feature walls. With the advent of sophisticated, bespoke window graphics, it’s now possible to use glass as a backdrop for creative digitally printed graphics which can easily be replaced and updated.

Talk to us about surface printing and the innovative and bespoke solutions we can create and deliver for your next project.

FAQ's

Can you help me with my artwork? Yes, our in-house design team can support you.

I’m not sure what product I need. There’s so many how do I choose? Yes! Our expert team can help choose the perfect material for your project.

How do I measure the space I want to add graphics to? Please send your measurements in mm, this will allow us to quote. If you need support measuring, our team can help.

Will I get a proof before it goes to print? Absolutely! All artwork is proofed before we send it to print. Any questions, we’re happy to discuss.

Examples

PRINTING TO PLYWOOD

Plywood can be a beautiful surface, particularly Poplar Plywood. Its smooth pale surface with a light woodgrain texture makes for a wonderful base. The naturally stripy edge makes a lovely feature. Our white-ink technology means we can print white text or areas for your design to really stand out.

When printing to plywood it is imperative that it is truly flat. Choosing a deep plywood such as 12mm or 16mm is best because the weight will help it pull flat. Plywood sheets should lay flat for at least 24 hours before printing.

These plywood panels were a few of hundreds that were displayed together the National Memorial Arboretum. Each one printed to and cut to shape. You can see the full case study here.

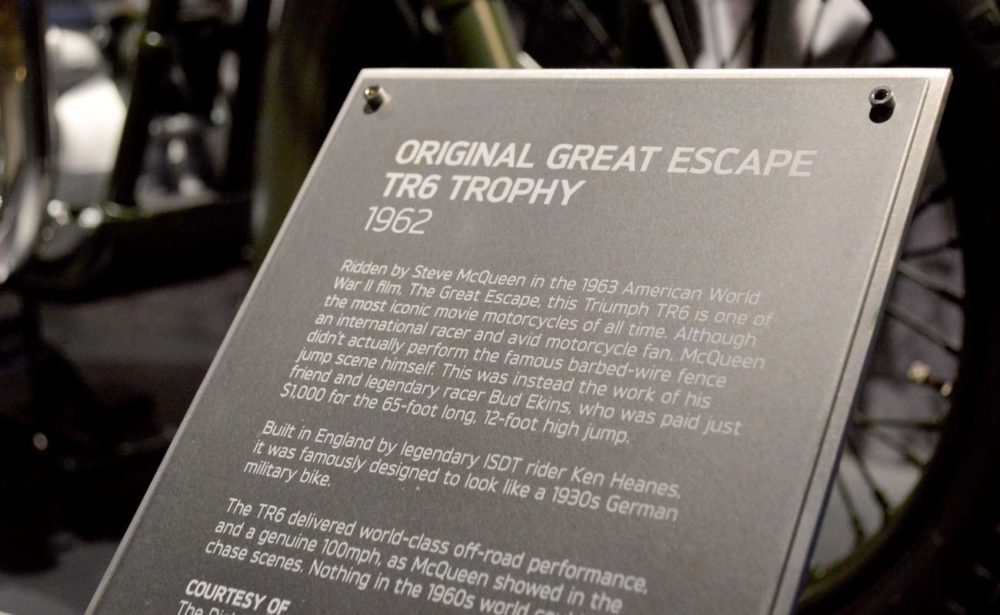

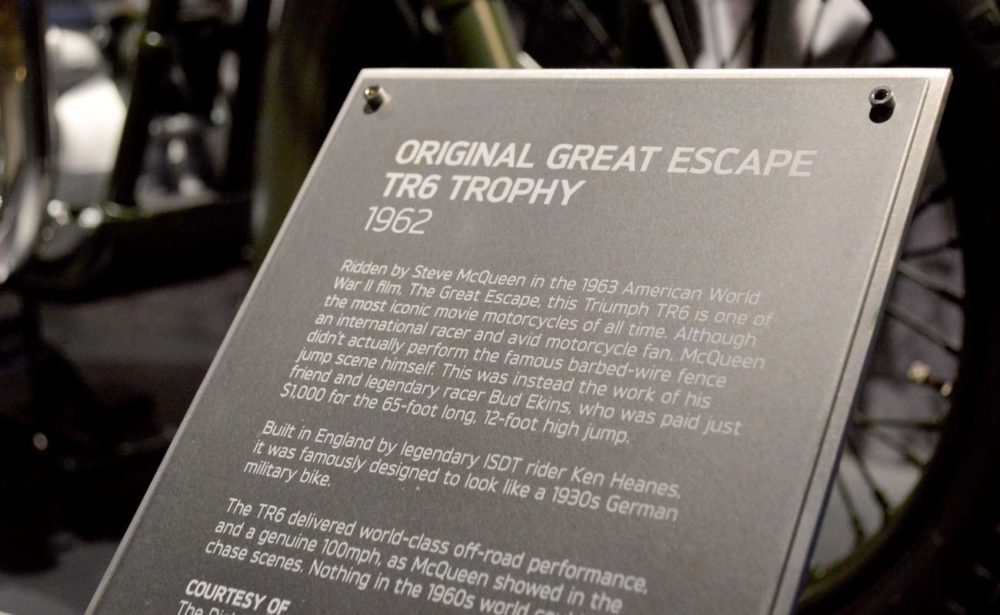

PRINTING TO METAL

These specially made aluminium displays were interpretation panels at the Triumph Motorcycles Visitor Centre. They were fabricated and folded to be self-supporting, but we couldn’t print to them if they weren’t flat. So we printed to a separate smaller panel that elegantly bolted onto the main display. This also meant that the display could be changed and the bolted panel updated.

It is important the we perform tests when printing to metal, to ensure the ink will key to it. Special coatings or finishes may affect the print and cause it to rub away or scratch off.

Get in touch with us to discuss printing to metal so we can plan testing and ensure you get the right result for your project.

APPLICATIONS

- Office Interiors

- Retail displays

- Educational boards

- Signage and wayfinding

- Events and Exhibitions

- Hoarding boards

- Furniture

BENEFITS

- Get a fresh, new finish to wow your audience

- Discover new effects and finishes

- Get your creativity noticed

- Challenge the status quo

- Be a pioneer!

- We'll support you with testing and finding the right solution